The ridge of a pitched roof is a detail too important to ignore, holding both aesthetic and structural significance. It sits at the apex, where two roof slopes meet, serving as the keystone of the entire roof structure. When constructing or refurbishing a roof, homeowners and professionals face a pivotal decision: whether to choose a traditional cemented ridge or opt for a dry ridge system. Each option comes with distinct advantages, challenges, and long-term implications for performance, maintenance, and compliance with modern standards.

Function and Importance of a Roof Ridge

A ridge isn’t just about capping tiles for visual completeness. This component plays a critical role in weatherproofing, linking the slopes and protecting against rain, wind, and debris. It also provides the final line of defence against water ingress at one of the roof’s most vulnerable points.

Securing this line must be approached thoughtfully. Poor workmanship or unsuitable materials here can undermine the whole roof, leading to costly problems. Ultimately, the choice between dry ridge and cemented ridge systems shapes not only visual harmony but also resilience and future upkeep.

Cemented Ridge System: Strengths and Shortcomings

The cemented ridge method has dominated British roofs for centuries. Here, ridge tiles are bedded onto a mortar (sand and cement mix), which binds the tiles securely to the roof apex. The finished result possesses a certain timeless appeal, blending seamlessly with traditional builds.

Advantages of a cemented ridge:

- Visually authentic, particularly for heritage or conservation projects

- Offers robust initial security

- Time-honoured approach recognised by many experienced roofers

Yet, there are aspects that deserve careful consideration. Mortar is susceptible to cracking over time due to environmental movements—thermal expansion, contraction, or roof ‘settling’. Once fissures develop, the risk of water ingress grows. Cemented ridges may eventually require substantial ridge repairs or re-bedding.

Common issues associated with cemented ridges:

- Brittle over time, prone to cracking and displacement

- Maintenance can be labour-intensive and sometimes hazardous

- Weakened mortar is vulnerable to extreme weather

- Repair often involves complete removal and replacement

The limitations are particularly evident in the context of changing building regulations and insurance standards, which increasingly favour resilient, low-maintenance roofing solutions.

Dry Ridge Systems: Modern Solutions for Today’s Roofs

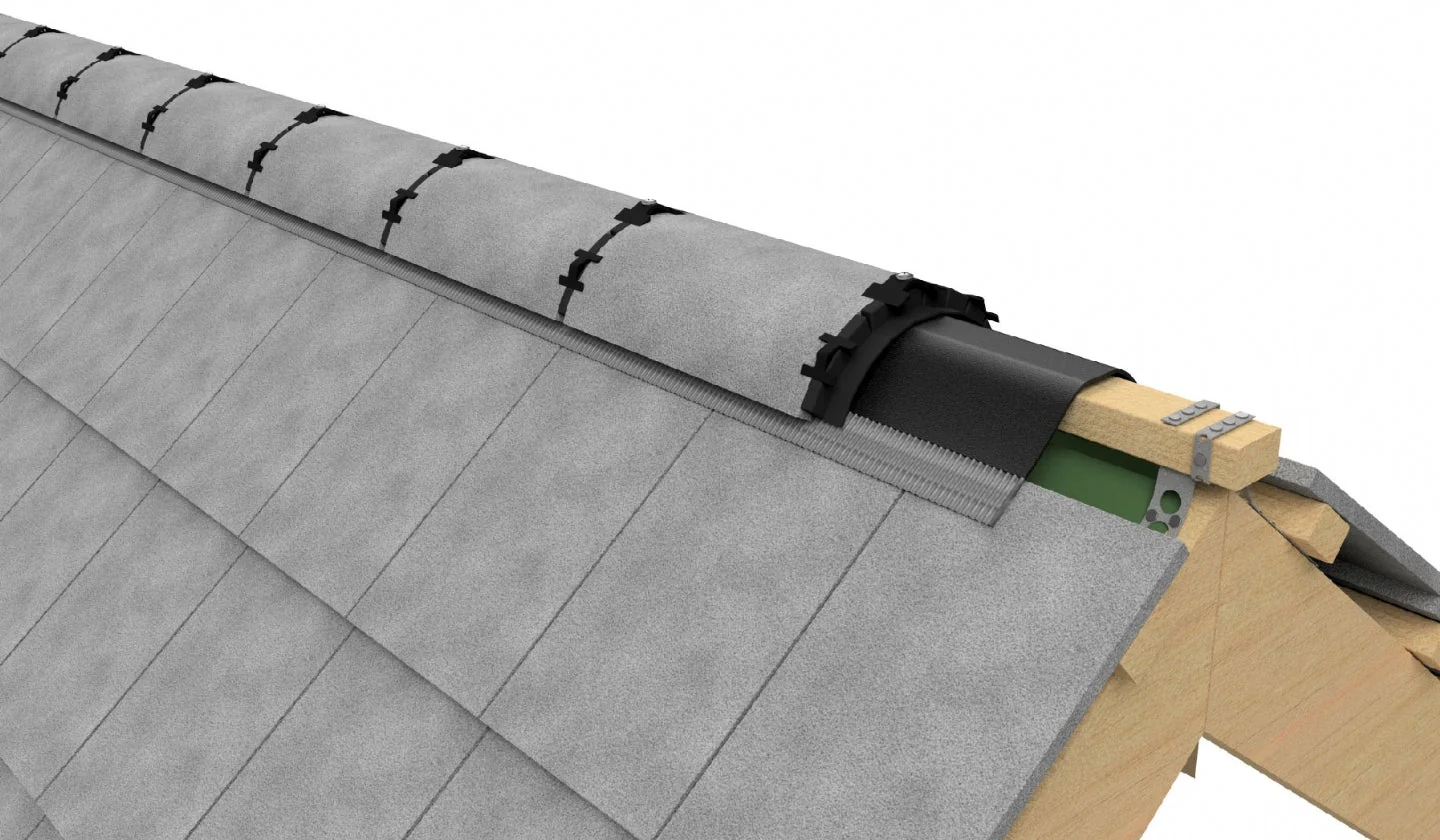

Responding to the drawbacks of mortar-bedded ridges, the dry ridge system has gained traction across both new builds and re-roofing projects. Developed with longevity, safety, and ease of installation in mind, these systems rely on mechanical fixings—rails or clips—rather than mortar.

The ridge tiles are mechanically secured to the roof structure using fixings and a breathable, waterproof membrane. This not only ensures a firm hold but also allows for controlled movement, important for coping with shifting roof structures and thermal changes.

Benefits of dry ridge systems include:

- Exceptionally durable in the face of wind uplift and storms

- Virtually maintenance-free after installation

- Improved ventilation, reducing condensation and mould risk

- Compliance with most updated British Standards (BS 5534)

Let’s put the two side by side:

| Feature | Cemented Ridge | Dry Ridge System |

|---|---|---|

| Fixing method | Mortar (sand and cement) | Mechanical (clips, rails) |

| Maintenance requirement | Moderate to high | Low to negligible |

| Ventilation | None | Enhanced, via membranes |

| Weather resistance | Variable, can degrade | Long-lasting, robust |

| Required by modern regs | Rarely | Often |

| Aesthetic flexibility | Traditional, limited | Range of profiles available |

Compliance and Insurance Implications

Recent changes in British Standards for roofing (notably, BS 5534) clarify expectations around mechanical fixing. The standard was updated in response to repeated incidents of storm damage, particularly the wholesale failure of mortar-bedded ridges under high wind.

Many insurance providers increasingly scrutinise roof construction methods, particularly after a claim. Some may even require proof that a pitched roof’s ridge meets current standards before providing cover or settling claims for storm or water ingress damage. This is especially prevalent in exposed locations prone to strong winds.

Choosing a dry ridge system often simplifies these conversations. Mechanical fixing is now seen as best practice; it minimises the risk of tiles becoming dislodged and reduces the potential for subsequent water damage. Inspectors and insurers tend to view dry ridge installations more favourably, potentially lowering risk profiles and, in some cases, affecting premiums.

Ventilation: Moisture Management for Healthy Roofs

One fundamental difference between dry ridge and traditional mortar systems is ventilation. While old cemented ridges generally create a sealed ridge line, dry ridge systems feature built-in ventilation, facilitated by a permeable ridge roll or membrane. This design lets moist, warm air escape from the roof space, preventing condensation build-up.

Why is this important? Modern living generates a substantial amount of moisture (through cooking, bathing, breathing). If this moisture cannot vent from the roof, it can condense on cold surfaces within the loft. Over months or years, this moisture causes timber decay, roofing felt degradation, and the potential for unhealthy black mould.

With a mechanically-fixed, ventilated dry ridge, continuous airflow is maintained along the apex, supporting the overall health of roof timbers and insulation. Many newer homes, and even older properties being re-roofed, are now routinely upgraded to include this feature.

Installation: What to Expect

The method of installation for each system is very different. Cemented ridges require skilled craftsmanship; working quickly yet methodically with mortar, followed by several hours for setting. Dry weather is a necessity. If conditions aren’t ideal, there’s an increased risk of suboptimal bonding.

Dry ridge systems, by contrast, may look high-tech but are often more straightforward to fit. Installers use universal kits containing all fixings and membranes, and the process can be performed in almost any weather since it doesn’t depend on the curing of mortar.

A typical dry ridge installation usually involves:

- Laying a vapour-permeable ridge roll along the apex

- Mechanically fixing ridge tiles using the supplied system

- Ensuring cap tiles are aligned neatly for a clean finish

- Double-checking fixings for security and weatherproofing

Homeowners benefit from rapid installation and minimal disruption. Many roofing contractors report that dry ridge systems can halve the installation timeline compared to cemented ridges.

Aesthetic Considerations

Authenticity is often a deciding factor, particularly for those renovating older homes or working within conservation areas. Cemented ridges can deliver an ‘original’ look, with bespoke pointing and the soft weathered lines associated with historic craftsmanship.

Some, however, feel that modern dry systems lack visual subtlety. This perception is gradually changing as manufacturers provide a broader palette of cap tile designs. With careful specification, dry ridge systems can suit even sensitive projects, particularly when using traditionally-profiled ridges or matching the finish to existing roof tiles.

Longevity and Long-Term Cost

Where the cemented ridge once won on outright stability and cost, the conversation is shifting. Dry ridge installations typically command a marginally higher up-front investment, due to the mechanical kit components and membrane. However, their durability and minimal maintenance often generate meaningful savings over the life of the roof.

Factors impacting total cost of ownership:

- Reduced need for future repairs or re-bedding

- Lower risk of tile loss after storms

- Fewer scaffolding requirements for emergency maintenance

- Improved building ventilation supports overall roof health

Investing in a dry ridge could be seen as an upfront outlay that pays dividends in reduced repair bills, fewer disruptions, and increased compliance.

The Decision in Practice: Which Suits Your Roof?

Each house, location, and budget is unique. Some periods properties may still be best served by traditional techniques, particularly under strict planning controls or where blending with neighbouring roofs matters. Skilled roofers can still achieve robust results with mortar, provided they use modern additives and pay extra attention to detailing.

Yet, for new builds, re-roofing work, and properties in exposed environments, the case for mechanical dry ridges is compelling. Durability, safety, and an insurance-friendly status make them ever more common on British roofs.

Key considerations when choosing:

- Regulatory requirements

- Local planning or conservation rules

- Exposure to wind and rain

- Long-term maintenance preferences

- Desired appearance

Professional advice from a reputable roofing contractor will take these factors into account, enabling a choice that balances tradition, performance, compliance, and budget.

What Every Homeowner Should Remember

The roof’s ridge is more than just the finishing touch; it’s a critical line of defence and an architectural statement. Whether selecting traditional cement or embracing the innovations of dry fix, understanding the implications helps ensure a safe, beautiful, and enduring roof for decades to come.